Okay, I'm no clutch expert. I've replaced more than a few of them, but usually because they were flat worn out or a clutch related part failed (pilot or throwout bearing, oil seal, etc)... or maybe for a performance upgrade, or more often a "just because the engine is out" replacement. And the important part, I've never really looked at them all that closely. Sometimes they're worn, sometimes they're not. Never really gave it much thought, but mostly just looked at friction surfaces. I guess I'm just getting more curious in my old age.

I did learn a couple years ago with a lightweight Miata project that an "unsprung hub" clutch disk is a pretty awful thing to drive. Those little springs in your clutch really do have a purpose! We'll come back to that.

The purpose of this thread isn't really to provide any conclusions. Merely some discussion, food for thought, and perhaps enlightenment based on my measurements and observations of the Mirage clutch that I happen to have on my kitchen table. (and the wife hasn't complained... maybe she finally gave up?) Opinions, experiences and feedback are welcome.

So, what I have before me is a 40,000 mile Mirage clutch. The first 30k miles happened over 2 years, likely a highway commuter vehicle. The last 10k were all me over the past 15 months, mostly casual city driving, and 35 autocrosses (214 autocross runs with appropriately aggressive launches and hard 2nd gear shifts).

PRESSURE PLATE:

I've already sent the pressure plate out for recycling, so no photos. I'm replacing it just because it's out of the car. For $105, it's always worth replacing a clutch while it's out to extend the life of the clutch. The pressure plate was nearly perfect. The spring fingers had significant (but normal) wear where the throwout bearing makes contact. That surprised me a little bit, but they would go to at least 120-150k miles at their current wear rate. The friction surface was barely broken in. The factory milling marks were still very present in the middle of the contact area, only the outer edges were really worn-in. Never any problems with the clutch slipping, which means the clutch itself is probably slightly more than needed for the amount of power we have. (really surprising for ANYTHING to be that over-built on this car, the tendency is for everything to be as light as possible and just barely adequate for the extremes of what the car is intended to do)

FLYWHEEL:

Uh, well, honestly... I didn't look at it too closely. It definitely wasn't showing enough wear that I even gave it any consideration. Probably about the same as the pressure plate. It's been sent off to get lightened.

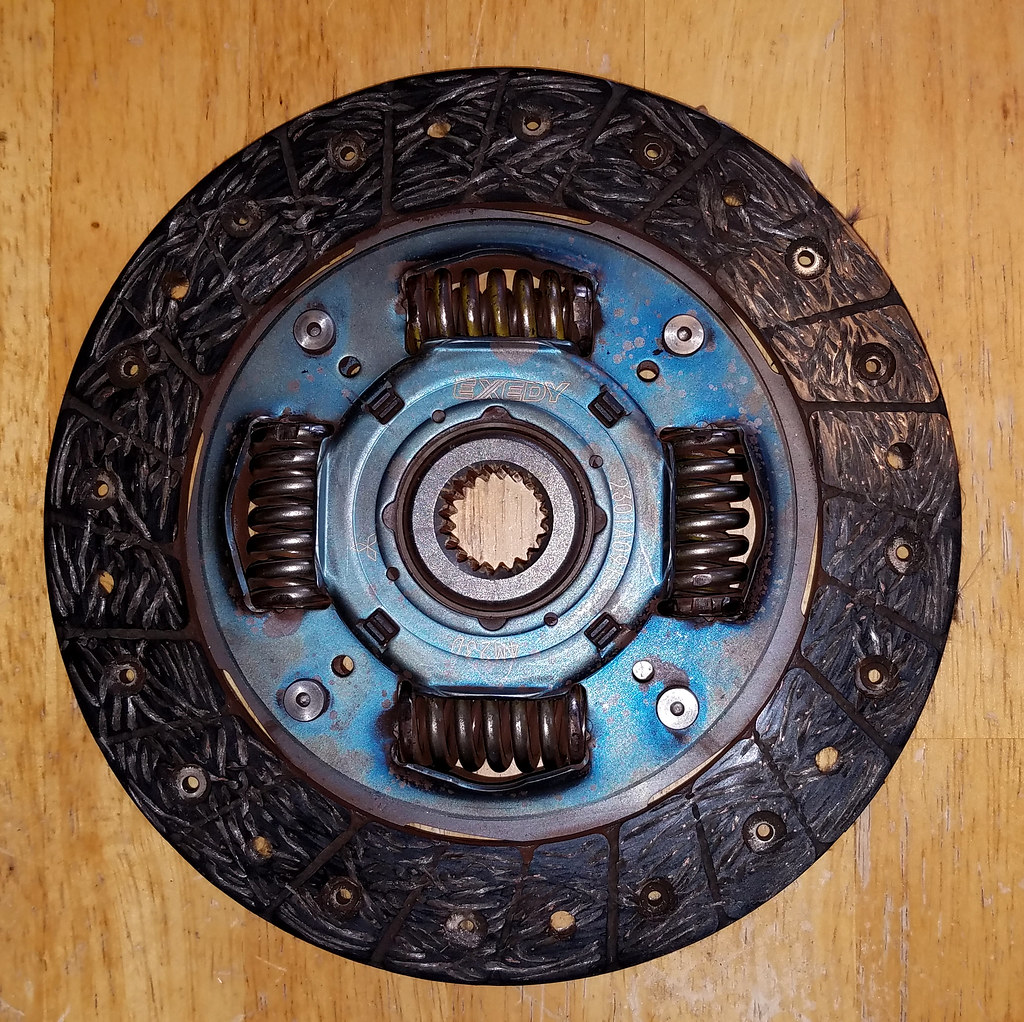

FRICTION DISK:

Ah, now this is the fun part. This car has always had a bit of a noisy clutch. Just a bit of a rattle at idle, and a horrible resonant buzz if you get on it too hard in reverse. (used to do it every time I backed up my driveway until I figured out that it didn't do it if I babied it) I figured I'd just not worry about it until it became a problem, got a lot louder, or I pulled it out to put in a lighter flywheel. May hand was forced when an engine problem required the engine to be removed... time to do the flywheel and clutch!

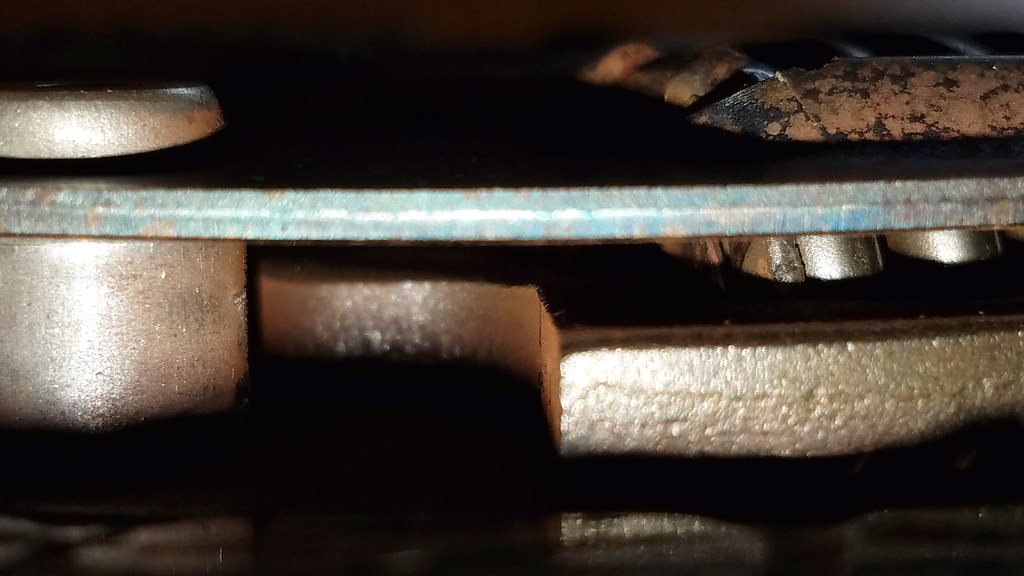

The only clutch problems I've heard of from this generation of Mirage have been noises similar to mine, and one clutch with a broken spring in the clutch disk. So, the first thing we're looking at is the clutch springs. There are four springs. Actually, eight. Each of the main springs has a smaller spring inside it. All of the springs are quite loose. They rattle, they rotate easily, and they can be moved foreward and back about 1.5-2mm. There's the noise I've been hearing.

But, that's not the worst part. Rotating the springs reveals that the springs are quite worn. Now, I don't know how much wear is "normal", but there's enough wear on these that I would expect at least one of them to break by 80k miles. The deepest grooves measure about 1.2mm. (the spring material is only 3mm thick)

BASIC SUMMARY:

Pressure plate and flywheel are fine. Very little wear for 40k miles. The clutch disk friction surface is also fine. The springs in the clutch disk are possibly a problem area, especially for an aggressive driver.

I'm gonna add two more posts here. One to expand on how the clutch disk works and what I think happened or is happening. (photos included) The other to compare the replacement clutch disk with the old and provide some interesting measurements that you're never going to need.

Underdog

Underdog

Reply With Quote

Reply With Quote

"Scarlett and Marsha"

"Scarlett and Marsha"

Cheap Plastic Car

Cheap Plastic Car

2015 Test Mirage

2015 Test Mirage Swarthy

Swarthy

Gloria

Gloria 2015 Mitsubishi Mirage DE

2015 Mitsubishi Mirage DE